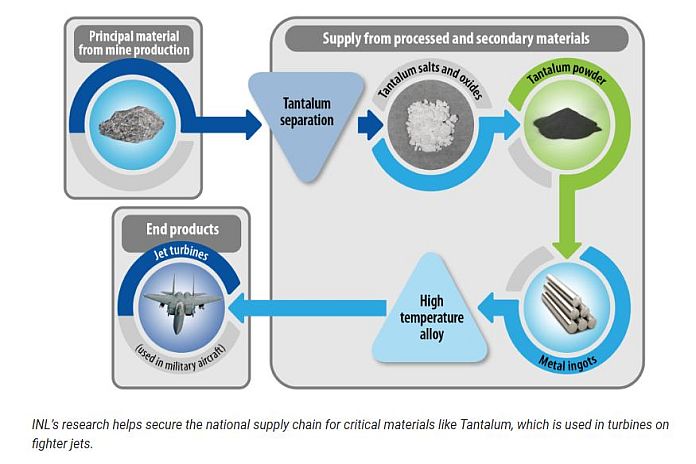

From satellites and surveillance systems to precision-guided munitions and fighter jet engines, critical materials are at the foundation of America’s military strength. Yet most critical materials are extracted and processed overseas, leaving the US vulnerable to supply chain disruptions that could jeopardise everyday life, economic stability and national security.

Securing a reliable domestic critical material supply chain is one of America’s most pressing challenges. The Idaho National Laboratory (INL) is helping address this challenge by researching ways to advance domestic extraction and processing technologies. The effort aims to reduce or eliminate the nation’s dependence on foreign sources of critical materials and support the mission of those safeguarding the US.

“National security efforts protect our way of life and allow us to go about our daily routines safely,” said Anthony Nickens, director of materials, manufacturing, and bioenergy science and technology at INL. “When Americans shop at a store or run errands, they don’t usually think about national security. National security is ultimately about identifying, deterring and sometimes engaging threats to safeguard the nation.”

The US has deposits of many critical materials, but due to economic factors, environmental regulations, lack of investment, outdated technologies and other challenges, the nation can’t efficiently extract or process them. While recycling and substitution offer partial solutions, not all materials can be recovered, recycling can’t keep up with growing demand, and substitutes often come with performance tradeoffs.

Overcoming these challenges demands sustained investment, innovation and coordination. To meet these challenges, INL is developing new technologies to enable sustainable mining, advanced separations methods and the production of high-quality critical material feedstocks.

INL’s research and development, and collaboration with other government agencies, national laboratories and industry and university partners, will reinforce the critical materials supply chain to support defense readiness and advance America’s interests in energy, technology and economic independence.

INL’s work

INL works closely with the Department of War and other government agencies to support every stage of critical material development, from discovery to deployment. In addition to research, INL provides specialised training for the Department of War, the Department of Homeland Security, other government agencies and first responders around the nation.

“Alongside nuclear energy, national security is a core part of our mission,” said Nickens. “INL has a long history of supporting the military. This work is in our DNA. Our roots go back to the birth of the Navy’s nuclear power program. Every nuclear-powered aircraft carrier and submarine traces back to work done here. Very few defense labs have the capabilities we do in terms of people and facilities.”

Another key attribute of INL is specialised capabilities for working with naturally occurring radioactive materials. These are substances in the environment that emit low levels of radiation due to the decay of elements like uranium, thorium and radium. The laboratory’s ability to work with these materials helps its researchers understand and manage critical materials that are found with or contain radioactive elements.

INL also leads in resource discovery and recovery of critical materials. Researchers use advanced geochemical analysis, artificial intelligence and autonomous systems to locate valuable materials in secondary, like electronic waste, and unconventional sources such as geothermal brines and mining waste. These tools allow for real-time exploration and analysis, identifying sources of critical materials without the need to open new mines.

INL is developing advanced chemical separation and purification methods to improve recovery rates and reduce waste. Researchers are automating these processes to increase speed, safety and scalability, which are key for real-world deployment. INL also supports material development and qualification for defense and manufacturing. Using advanced simulation tools, researchers test how materials perform under extreme conditions. Full lifecycle traceability ensures compliance with security and regulatory standards.

Facilities such as the Microscopy and Characterisation Suite and modelling platforms like Fracturing and Liquid CONvection and Multiphysics Object-Oriented Simulation Environment allow researchers to analyse materials at the micro and nanoscale and simulate their behaviour across the supply chain.

What sets INL apart is its integrated-systems approach. The lab combines chemistry, data science, robotics and systems engineering to accelerate innovation and deployment.

The critical and strategic minerals and materials initiative at INL

The Critical and Strategic Minerals and Materials Initiative develops solutions to secure a stable domestic supply chain for critical materials. By integrating artificial intelligence, market analysis, nonproliferation efforts and advanced manufacturing, INL leads pioneering research that supports America’s energy dominance and technological advancement. This includes:

- Developing efficient, environmentally responsible extraction and refining technologies;

- Optimising recycling of rare earth elements from end-of-life products;

- Researching alternatives to reduce dependence on scarce or geopolitically sensitive materials;

- Advancing manufacturing processes that reduce waste and improve material efficiency;

- Analysing supply chain vulnerabilities and recommending mitigation strategies;

- Supporting policy and regulatory development with scientific expertise;

- Training the next generation of critical materials experts.

INL is combining technical expertise with strategic partnerships with other government agencies, national laboratories and industry and university partners, to secure the domestic critical materials supply chain. This work ensures that the technologies and organisations protecting the US have the materials they need to face the challenges of today and tomorrow.